Features

At ADD.Q, we've dedicated ourselves to the art of precise sensor placement in press machines and analytical support, transforming raw data into actionable insights. Now, in collaboration with Eii Tech Solutions, we're excited to introduce Sensor Data Map (SDM).

This powerful, intuitive software is designed to transform the sensor data from your press machines into clear, actionable 2D and 3D graphs. SDM empowers you to visualize and analyze every "shot," helping you swiftly pinpoint the root causes of manufacturing defects, prevent costly production losses, and optimize your processes like never before.

1. Real-Time Graph Visualization: See Problems as They Happen

Imagine being able to see the health of your press machine in real-time, just like watching a live heartbeat. SDM's Real-Time Graph feature does exactly that.

- Live Data Monitoring: As your press machine operates and sensors, expertly placed by ADD.Q, collect data to your PC (in CSV format), SDM instantly reads this information. It then transforms these raw numbers into dynamic 2D and 3D heatmaps, showing you a visual representation of multiple production shots.

- Instant Updates: The graph updates and adds new shots automatically, giving you an immediate picture of your machine's performance. If anything unusual starts to happen—like a sudden rise in temperature or pressure—you'll see it reflected on the graph right away.

- Prevent Costly Defects: This real-time insight is invaluable. An experienced operator can spot a deviation from the normal pattern and potentially stop the machine before it produces a large batch of defective products, saving you significant material and time.

- Analyze Past Performance: Beyond live monitoring, SDM can also easily load and visualize data from saved CSV files, allowing you to thoroughly analyze past production runs to understand trends and identify when and why defects occurred. This helps you prevent similar issues in the future.

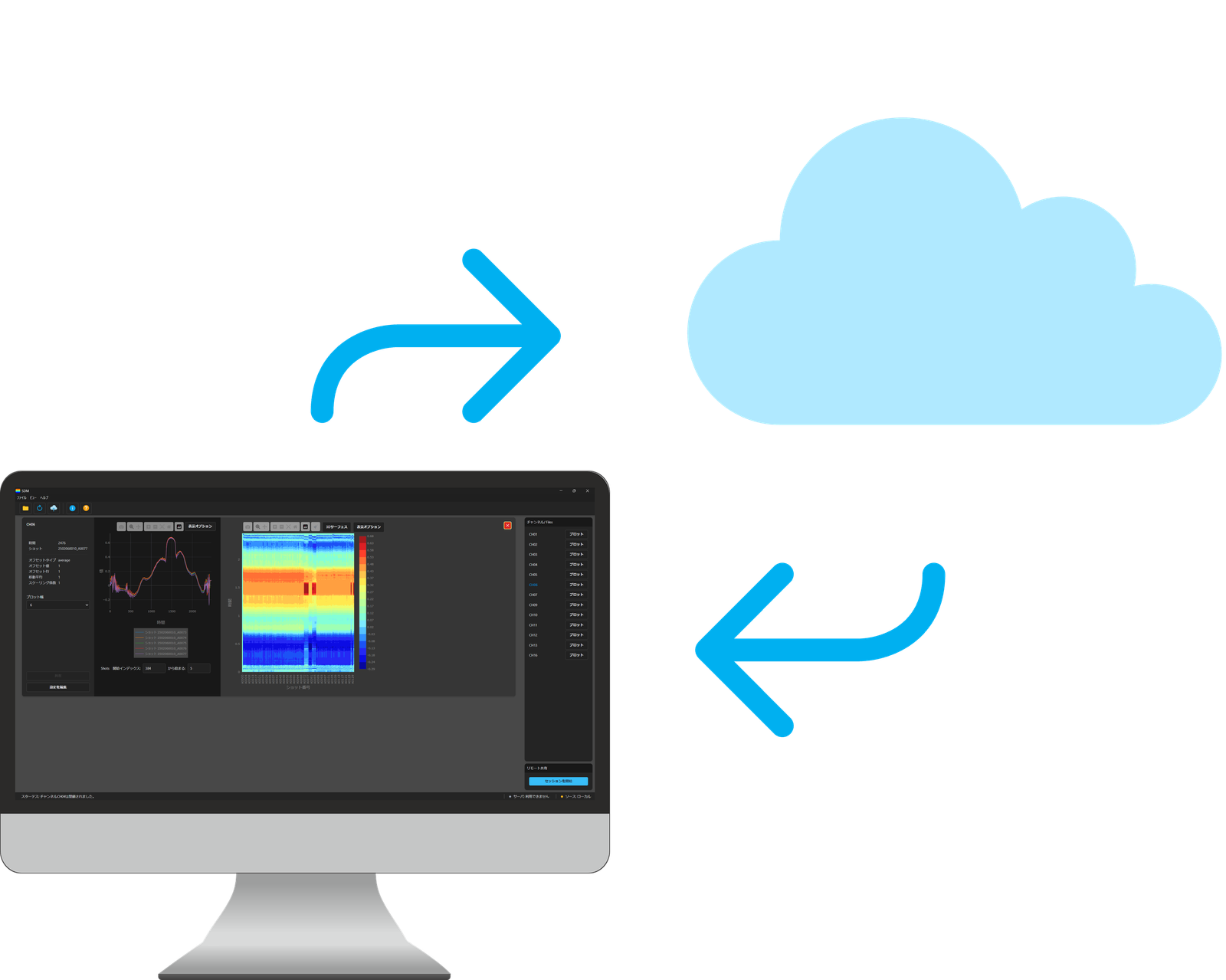

3. Cloud Storage: Your Data, Accessible Anywhere, Optimized for Efficiency and Security

Large sensor data files can quickly consume valuable storage space and make it difficult to access your crucial information across different devices. SDM's Cloud Storage solution solves this challenge efficiently and securely.

- Generous 100GB Storage: SDM provides ample cloud storage, ensuring you don't have to worry about running out of space for your critical production data.

- Access from Any Device: Store your valuable data in the cloud and access it from any of your devices, perfect for owners and managers who are frequently on the go.

- Compact & Efficient Storage: We utilize the advanced Parquet format to save your data in a highly compressed and efficient manner. This means your data takes up significantly less space in the cloud. For example:

-

- A single sensor channel with 5,000 production shots (CSV files), each with about 5,000 data values, would typically be around 500 MB as CSVs.

- With SDM's optimized storage, this same data would only occupy approximately 70 MB in the cloud!

- This incredible efficiency allows you to store roughly 1,462 of these channels in 100GB, compared to just 204 if stored as standard CSV files. This means more data, less worry, and better accessibility.

- Robust Data Security: We understand that your production data is sensitive. SDM is built with robust security measures to ensure your data remains private and accessible only to you. Your application is securely tied to your specific device using a unique activation process. All interactions with cloud storage are continuously verified through our secure server, confirming your credentials and authorized device access every time. This rigorous system ensures your valuable production data is protected and available only to you, on your authorized device.

Built for Performance and Ease of Use

Developed by Eii Tech Solutions with their web expertise, SDM is a native application for both Windows and Mac, engineered for robust performance. We've conducted extensive research to ensure that even with very large datasets (thousands of shots, each with thousands of data points), our real-time visualizations remain incredibly fast and responsive. We are committed to continuous improvement, ensuring SDM remains the most effective tool for your press machine data visualization needs.