Visualize your production

Identify your production errors in real-time.

- Real-time data visualization.

- Secure Cloud Storage.

- Instant Remote Share through advanced websocket technology.

Begin your 30-day free trial.

Request Demo

What is SDM for?

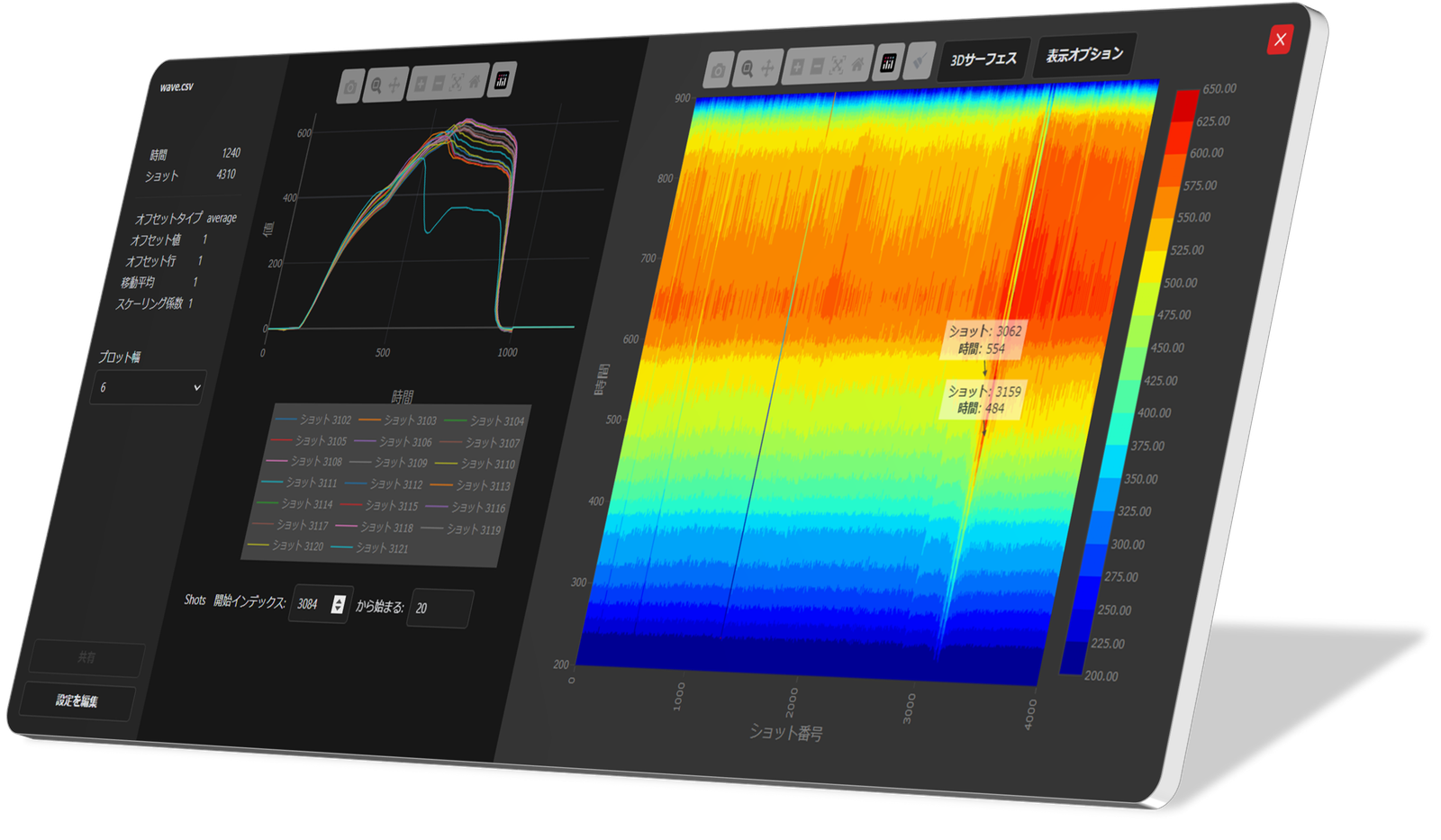

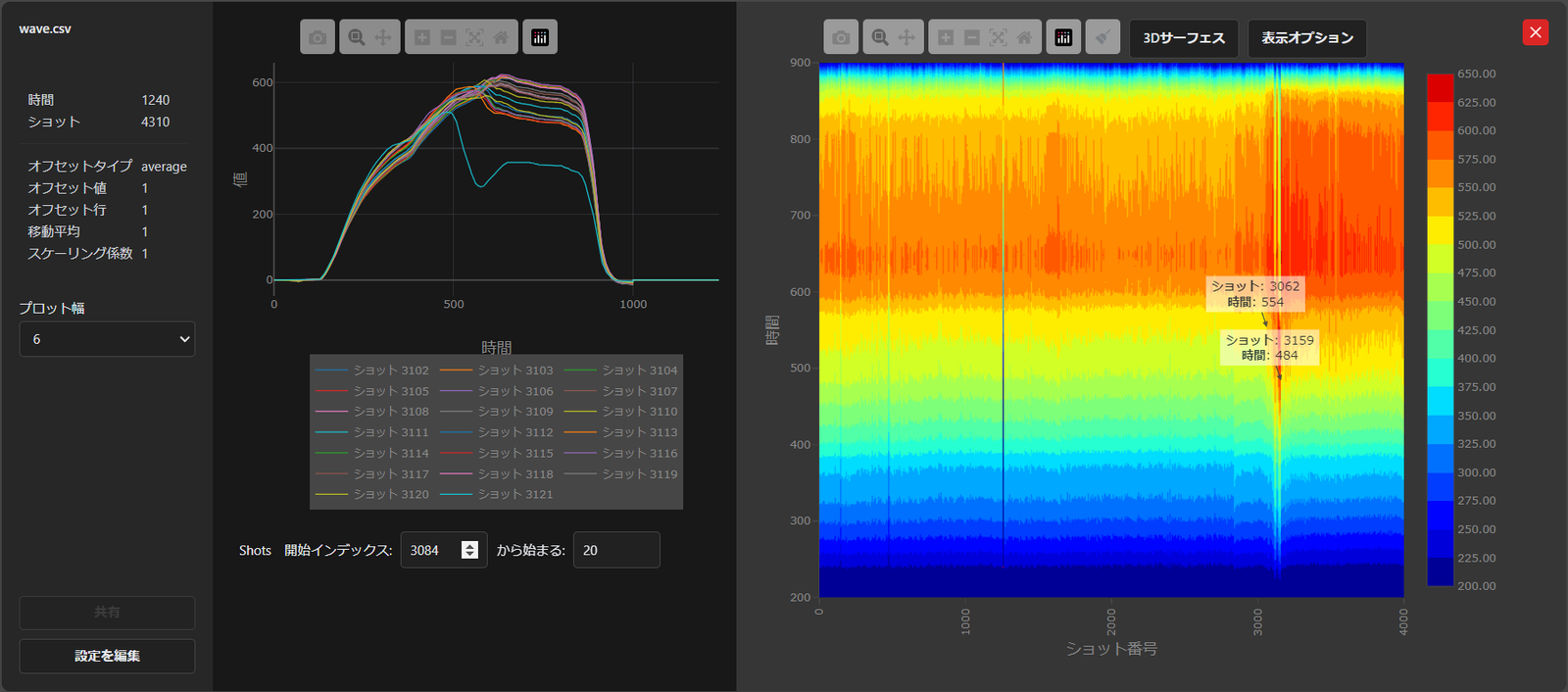

Sensor Data Map (SDM) is a powerful new software that visualizes real-time data from sensors installed on press machines and molds, and detects abnormalities during production or makes you aware of signs of abnormalities. Designed for industries that collect repetitive data of certain operations, such as press molding, resin molding, and automated assembly lines, SDM reads multi-channel data (load, pressure, temperature, displacement) and generates 2D heat maps and 3D surface graphs for each shot. This allows engineers to visually capture the molding load waveform for each shot, as well as the subtle differences in the waveforms for each shot that occur in consecutive shots. It is now possible to easily and timely capture the process leading up to an abnormal shot that was not visible until now, and it is now possible to capture signs of abnormalities.

In addition, it can easily visualize all kinds of repetitive data, such as subtle changes in pressure distribution, temperature changes, and the continuous displacement of slide position.

ADD.Q has been committed to continually raising the bar in sensor development, data visualization and data analytics since 2015. SDM is part of a next-generation approach to predictive maintenance and sensor-driven quality control.

Data shared by Paloma Co. Ltd.

Watch in Real-time

SDM makes it easy to visualize your production performance by reading the data collected from the machine sensors and converting it into a 3D heatmap instantly, which updates in real time, reducing your production worries.

Learn moreOptimized Cloud Storage

Forget about your storage problems!

SDM allows users to store and retrieve data from SDM cloud storage. It saves the data in a special compact format, providing more space when saving to SDM cloud.

Learn more

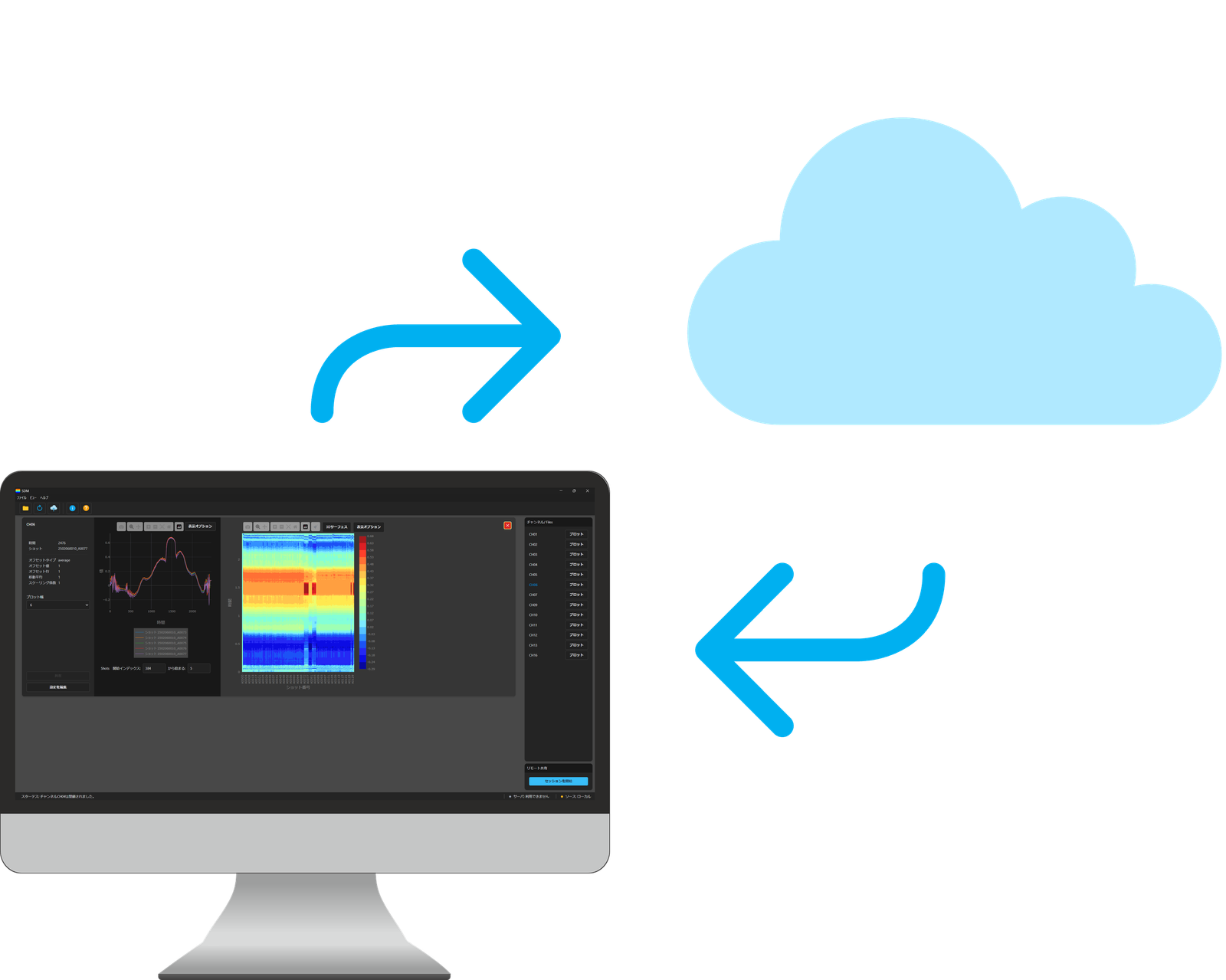

Remote Sharing

One of the most powerful features of SDM is the ability to instantly share 3D heatmaps with others in real time using advanced WebSocket technology.

With SDM, users can securely send visual data to another SDM user almost instantly—no need to save files, upload them, or wait for downloads. Unlike traditional file sharing, which involves multiple steps, SDM uses live, secure data streams to deliver the heatmap directly, just like sending an instant message.

This makes it incredibly convenient for teams to collaborate and share important visual data across departments or locations, helping everyone stay aligned and make faster decisions.

Learn moreFrequently Asked Questions

SDM is a software tool that reads data recorded from multiple sensors installed in the press machine (force sensor, displacement sensor, acceleration sensor, AE sensor, temperature sensor, etc.) and generates 2D and 3D graphs in a timely manner. These graphs are very useful for detecting abnormalities and predicting abnormalities during the press cycle.

It helps identify issues such as:

- Fluctuations in forming load.

- Pressure distribution fluctuations.

- Change in bottom dead center position.

- Abnormal temperature change.

- Vibration inconsistencies.

These problems can lead to production defects, tool damage, or costly downtime.

SDM can read CSV data measured by any data collection device. In the future, we will develop it so that it can directly import binary data from major data collection device manufacturers (Kyowa Electronics Co., Ltd., Keyence Corporation, Riken Keiki Nara Seisakusho Co., Ltd., etc.) before CSV conversion, aiming for a more timely display.

Yes. SDM can operate in real-time mode to display live graphs of each press cycle as it happens, or in analysis mode to inspect historical data (individual or multiple shots).

Accuracy depends on correct sensor placement and machine-specific data. ADD.Q is specialized and provides services on optimal sensor layouts and analytics. With proper sensor and sensor placement, SDM can be very useful to detect errors.

Not yet. This way of visualizing the production error is comparitively new and not yet adopted by many manufacturers. Alerting and automated diagnostics are part of the planned future features as more data and case studies will be available for learning.

Yes, SDM is optimized for the automotive and metal forming industries, but can be adapted to any industry where multiple repeat data acquisition is required.

It is a combination of both. The software is a locally installed application ensuring high performance while reading and generating graphs. It can work in both Windows and MacOS. User can store the data in clouds storage which can be used in other devices through installed software.

This feature is only available with Pro Subscription of SDM.

Using Remote share, a user can share any graph instantly with other users. The reciever(s) can view and interact with the graph as the sender. This is a very useful feature for collaboration with teams and collegues reducing geographic boundaries and futuristic working environments.

This feature is only available with Pro Subscription of SDM.